Institute of Mechanical Engineering with automatic welding equipment Couplings

To install build the pipelines, often using two methods of pairing: the grafting with flange and coupling by welding method. The downside of this method is low labor productivity, weld quality is unstable, workers made very difficult, even easier labor insecurity and in many cases the only Couplings be conducted in factories, is not applicable in the field of pipeline construction and major long.

To install build the pipelines, often using two methods of pairing: the grafting with flange and coupling by welding method. The downside of this method is low labor productivity, weld quality is unstable, workers made very difficult, even easier labor insecurity and in many cases the only Couplings be conducted in factories, is not applicable in the field of pipeline construction and major long.

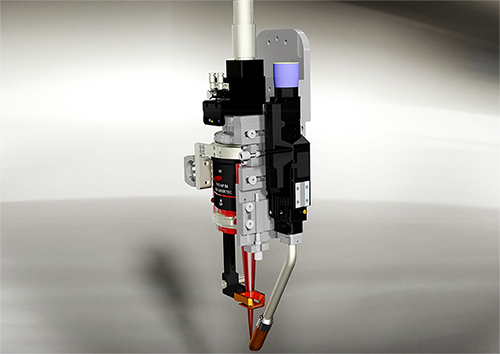

To overcome these difficulties and limitations, speeding construction works and improve quality of connection pipelines, Engineering Research Institute has successfully implemented and has been accepted officially Topic State-level "research, design, manufacturing systems automation welding equipment with large diameter pipe in a state of motion."

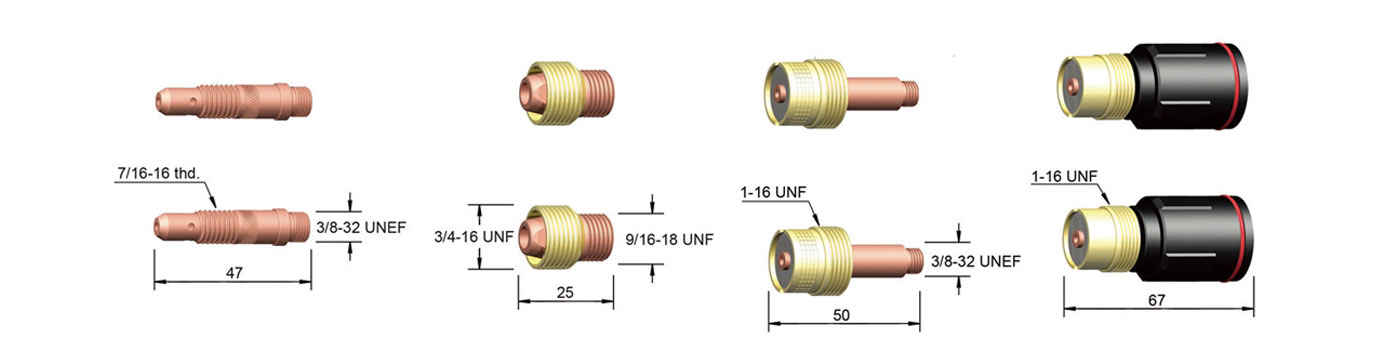

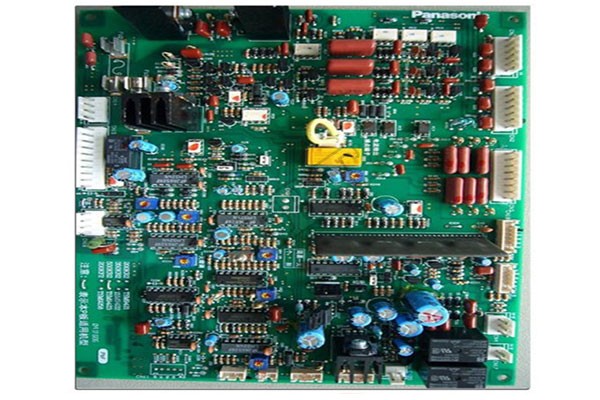

This is a technology research and new welding equipment, used for manufacture of pressure pipes serving the small and medium hydropower projects. Thanks to the automation of welding wire feeder, automatic translation correct orbit welding speed that can accurately locate stable arc groove, welding productivity growth was many times with welding rod welding crafts hand, especially for beautiful weld quality and stability.

System automatic welding equipment of large diameter pipe in turning state of the subject has not been applied and put into practice successfully produced for welding pressure piping Nam Khanh Hydropower projects in Bac Ha , Lao Cai. The result is highly appreciated products, ensuring the technical requirements and quality welding technology.

The success of the project opened up a new IT application for the construction of hydropower projects in Vietnam. The transfer of the research results of the research will be oriented technology transfer package or contracted to undertake the economic construction of large diameter welded pipes in a state not at the scene by turning the device system , technology, materials and technical employees of Laboratory Technology Core Welding and Surface Treatment - Engineering Research Institute.