New Welding Technology for ships transporting natural gas in the Arctic

Hyundai Heavy Industries (HHI) of Korea recently announced plans to develop a special welding technology for tank transport LNG liquefied natural gas in the Arctic region.

Hyundai Heavy Industries (HHI) of Korea recently announced plans to develop a special welding technology for tank transport LNG liquefied natural gas in the Arctic region.

This is part of a long-term strategy of the company for the increase in demand for LNG FPSOs and LNG transport is used in the polar regions. This also shows the growing interest in exploiting natural gas in the polar regions. HHI expects to make a foray into LNG carriers in the polar regions and market LNG FPSO projects gas development in the Arctic Ocean, which is estimated to have 44 billion barrels of natural gas, or 30% of natural gas reserves in the world.

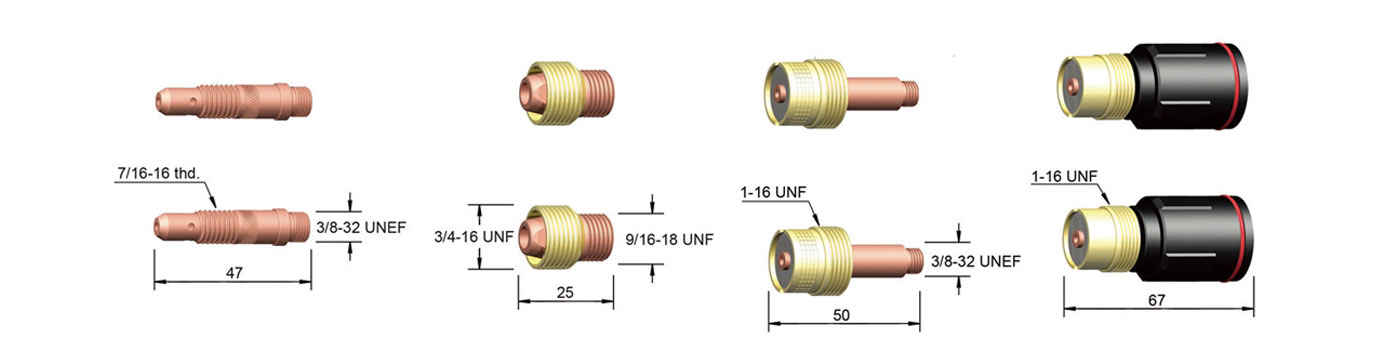

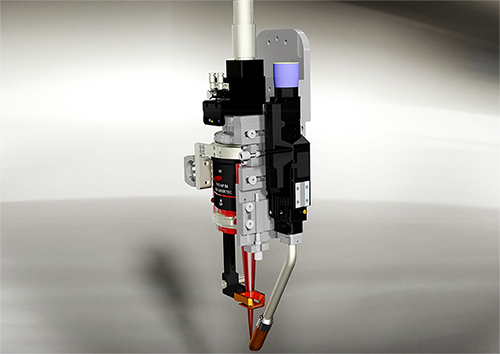

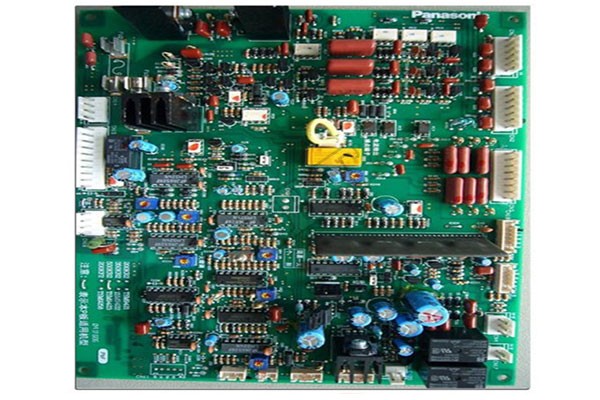

The objective of this project is to build a system of special welders can weld the thick aluminum plates used for the LNG tanks. Highly developed welding skills are needed to build LNG storage tank as the demand for safety in the cold polar regions requires thickness of 50mm to 70mm plate is.

By developing welders and welding car with new designs, HHI is expected to increase the amount of weld metal from 35g to 60g per minute and hope to improve welding speed and capacity to over 30%.

After the ship first LNG carrier to be closed in 1994, HHI now has a fleet of 37 tankers with LNG.