The new laser welding technology

A new welding technology is the researcher at the Russian Academy of Sciences found that allows laser welding combined with the addition of nano particles operations and uses ultrasonic vibrations resonate to improve including welded structures. This technology standards for better mechanical properties compared to traditional methods.

A new welding technology is the researcher at the Russian Academy of Sciences found that allows laser welding combined with the addition of nano particles operations and uses ultrasonic vibrations resonate to improve including welded structures. This technology standards for better mechanical properties compared to traditional methods.

Now there are many methods and welding processes. However, the weld is achieved by the welding process is still reliable and low mechanical parameters than the basic materials. So is it possible to achieve quality welds mechanical-physical properties as the base material? The answer is maybe if solved a critical problem - ensuring high quality of the material in the weld, preventing the formation of the crystalline structures and bubbles hole.

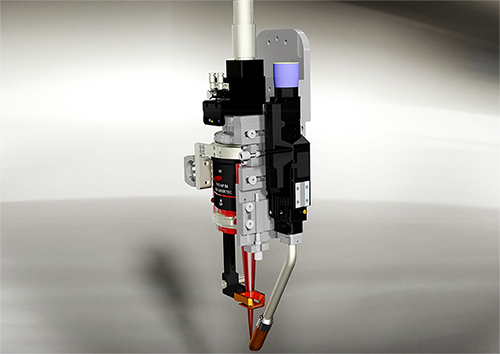

Unlike conventional welding, the laser does not melt the material: it goes into the material and the material forming the desired structure when combined plus special nano particles. Dust particles become linked crystalline blocks prevent crystal formation reduces the material's strength.

The increase in volumes linked crystal fragment welding materials. The movement of the laser to facilitate the mixing nano particles of seats in all welding positions, giving perfect weld with mechanical properties are achieved as basic materials. The nanoparticles are created specifically for inclusion in the weld.

Achievements on shows that the use of nanoparticles and ultrasound may improve the structure of welding materials, giving welds with high strength and fine arts. According to Russian researchers, this technology can make revolution in a number of industries.