Welding equipment confrontation reinforced concrete for buildings

The method of connecting the current rebar used in construction sites are varied and plentiful. However, in addition to advantages such as not too complicated, do not require high technology and equipment, easy to apply, v v ..., this method has many shortcomings to be addressed, such as low productivity, difficult to control quality, low load-bearing capacity, etc ....

The method of connecting the current rebar used in construction sites are varied and plentiful. However, in addition to advantages such as not too complicated, do not require high technology and equipment, easy to apply, v v ..., this method has many shortcomings to be addressed, such as low productivity, difficult to control quality, low load-bearing capacity, etc ....

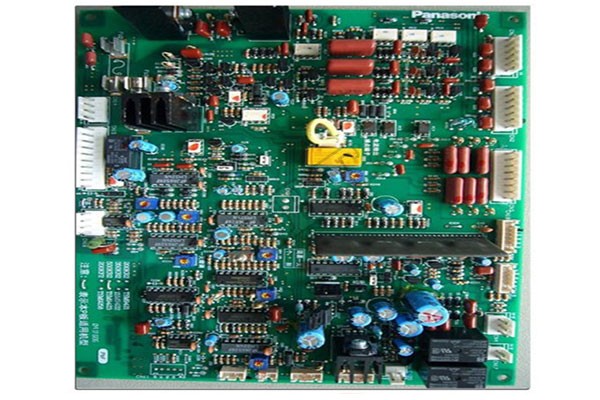

To meet the increasing requirements in terms of productivity, quality of large construction projects in the country as well as international, Engineering Research Institute has successfully implemented municipal topic: "Research application design, manufacturing technology and welding equipment welding confront concrete reinforcement in high-rise buildings. "

Electric slag welding technology is the advanced technology, the welding process is done in the environment is protected very well should be able to create the weld quality and high productivity, fully applicable to confront core solder connections steel construction.

By studying the characteristics and technological steps of the method of electric welding slag, combined with external pressure.

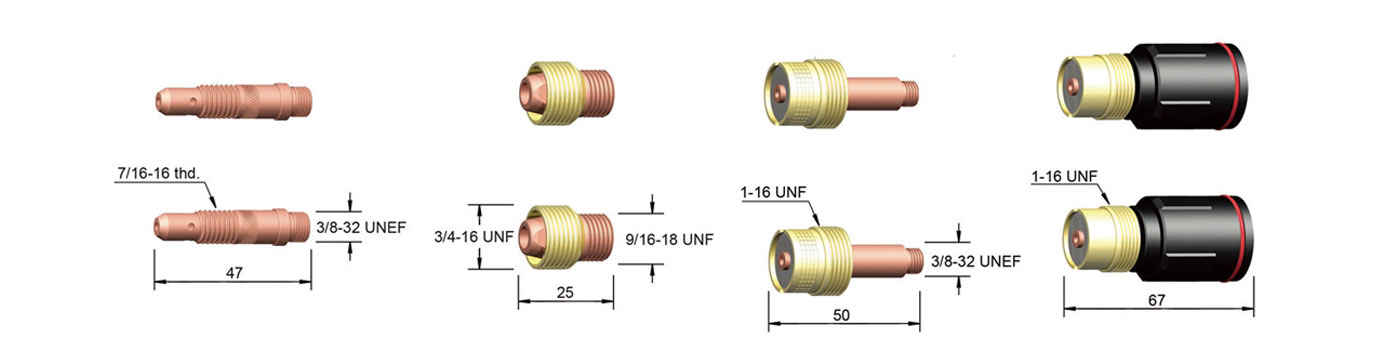

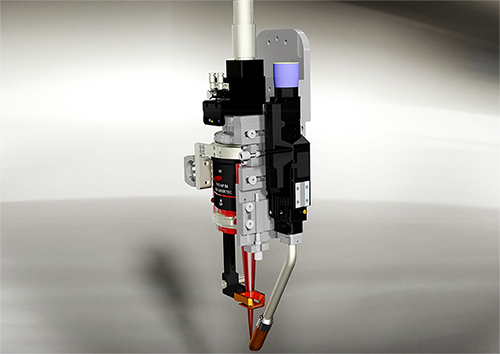

The main model for butt-welding two steel plants are described as Figure 1: Two-piece steel rod to be positioned directly connects mind and confront each other through the upper and lower jaw of a welding jig. Welding fixtures are designed especially to be able to adjust the distance between the two steel plants also creates pressure at the end of the welding process. Steel tree bottom is connected to the pole (-) of the welding machine welding pliers through 01, upper steel plant is also connected to the terminals (+) of the welding machine through 01 different welding pliers. Around joints are surrounded by a funnel drugs through drug solder.

With such models, the steel plant would be below the weld metal, steel tree top is electric slag welding electrodes. Welding drugs now have two major roles, under the effect of drugs arc welding will melt and form liquid slag, and the amount of drug being welded around the melting will act as sliding pads wrapped impulse around to create an ash.

In the initial position, the two ends exposed steel plants together, then by crank adjustment of fixtures for welding positions, two top steel plant apart. This time under the effect of welding voltage (40-42V), between two steel plants occurred early discharge arc at very high temperatures, will melt the entire surface of the two ends cross section steel plant contract as well as the surrounding molten solder drug. When the dose is large enough molten solder to form a slag pool, welding fixtures will push toward the top steel plant slag pool. At this point arc turns off, the voltage drops welders 22 - 25V, electric current passes from the top down steel plant steel plant via tank bottom ash, the electrical current heats the slag pool, maintaining it at a temperature altitude and high conductivity. Slag bath temperature is higher than the melting temperature of the steel plant. Therefore, the steel plant will continue to be melted at high temperatures of the slag pool.

When sufficient amount of molten metal to form seamless link, immediately, welding fixtures will perform the first cycle presses two steel plants has melted together to form welds with greater cross section section steel plant.

But this time the weld pool is surrounded by high-temperature slag, does not have the cooling process of the sliding pads, so after welding the weld should keep the status quo in a certain time to cool and caking slag pool to solidify and protect weld metal.

Complete electric slag welding process pressure can be divided into 5 major technology step is expressed through the following figure:

The theme has also been designed, fabricated and welded cluster electric slag welding jig pressure (Figure 7)

Technology products and devices for electric slag pressure of topics was applied effectively in actual production, construction in some construction work

Findings of the study include: process technology, fabrication, equipment and fixtures for electric welding slag pressure welding confront the results reinforced the new study, the first to be studied and developed and application in our country. The inspection results, reason welds showed real quality guarantees high reliability, process technology and equipment suitable to construction conditions in the construction works. These positive results thus can fully meet the stringent requirements in terms of quality as well as productivity and cost when applied to large construction projects in Vietnam.